Aerial Work Platforms: Maintenance Strategies That Deliver Reliability and Safety

Focusing on equipment training, inspection and maintenance can ensure equipment continues giving technicians access to hard-to-reach areas.

Aerial work platforms provide vital access for maintenance and engineering technicians working in the toughest-to-reach areas of institutional and commercial facilities. From building facades and parking lot lighting to gymnasium and lobby ceilings, technicians have come to rely on the platforms – now generally referred to as mobile elevating work platforms (MEWP) – for critical activities.

In order for MEWPs to perform as safely and reliably, managers need to implement measures that workers use the equipment properly and that they inspect and maintain it as intended by the manufacturer.

Safety spotlight

The first step in MEWP safety is identifying the root causes of past accidents and near misses that have occurred while using similar equipment. The focus should fall on the top three accident causes: lack of training and experience; the use of dangerous methods; and the use of equipment that is not properly maintained or lacks safety devices.

Examples of common accidents are: an operator trapped between the work platform and a fixed object; a MEWP tipping over; an operator falling from the work platform; and a MEWP colliding with a pedestrian, a fixed object or a vehicle.

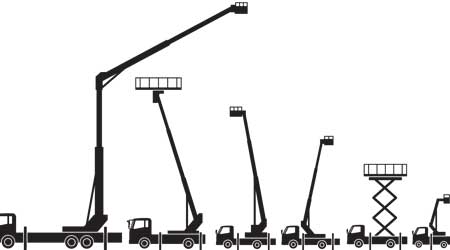

After reviewing these causes, managers need to match the type of MEWP to the activity or project. Among the MEWP types and their most common application are these:

Push-around vertical platforms are small scissor lifts often 11-16 feet tall that are used for indoor low-level, safe access in smaller warehouses and factories in place of ladders and steps.

Mast lifts are small boom lifts with a 13- to 32-foot height range that are designed for low-level access in tight, crowded spaces, such as retail stores, offices, commercial buildings and hotels not accessible by traditional scissor lifts.

Scissor lifts are large mobile units that are 25-108 feet tall that workers can use in both indoor and outdoor spaces requiring straight lifts. With their large platform area for workers, they might be difficult to maneuver in crowded areas, but they are available in rough-terrain versions and with double-retracting decks for better maneuvering.

Articulated boom lifts can reach up to 32-140 feet and have extensive movement ranges. Their horizontal reach makes them a practical solution indoors and outdoors and enables technicians to maneuver the platform around and over buildings and equipment. They are available in a range of sizes with features that include rough-terrain options, non-marking tires and power options.

Stick boom lifts, or telescopic boom lifts, can reach heights of 50-156 feet and offer an extensive range of movement similar to articulating boom lifts. The platform can extend sideways and reach heights that are designed for maneuvering around and above obstructions, equipment and buildings.

Track-mounted lifts, with heights 42-75 feet, are designed for access in outdoor areas where the ground is uneven. They can also be useful on steep inclines, in narrow areas and on stairs. Technicians also can use them for low-point loading and extended height and outreach. The tracks spread the weight more evenly to reduce ground pressure, making them more mobile on soft ground or in mezzanines.

Truck mounted lifts with a range of 65-180 feet, are designed for travel between several sites. With extended height and horizontal reach capabilities, they are commonly used outdoors for installing signage and telecommunication systems, high-level parking lot lighting, and video-recording before-and-after conditions.

Training tactics

Once managers have reviewed accident causes and selected the most appropriate type of MEWP for the application, the next step is to prepare a list of needed training materials. These often include the manufacturer’s operation and maintenance manuals, safety manuals, service manuals, and preventive maintenance (PM) guides. Managers also need to provide technicians with safety data sheets for products such as lubricant, cylinder fluid and battery fluid.

The prestart inspection for MEWPs must include locating these documents on the equipment, verifying that the equipment is in good operating condition and ensuring all workers have an opportunity to review the training material before operating.

Since the most frequent cause of accidents is improper operation due to lack of training and experience, workers must receive professional training, as well as adequate opportunity to practice to ensure their full understanding of safe and equipment-friendly operation.

Due to the ever-changing coronavirus situation, managers must ensure that workers receive every training opportunity consistent with the local coronavirus condition. Many trainers are limiting size of classes or providing self-paced, remote learning in place of classroom training. Technicians also must offer personal protective equipment (PPE) for practice sessions. This PPE includes masks and gloves, as well as hard hats, safety shoes and ear protection. Training plans also must include hand-washing and social distancing.

Inspection insights

A detailed prestart MEWP inspection must cover the following areas:

- Check that there are no loose parts and no visible damage to the platform, ladder, handrails or deck.

- If the unit is unsafe, lockout and repair it.

- Turn off the motor during inspection.

- Make sure the battery is fully charged, connected securely and grounded.

- Ensure there are no missing parts and that all placards are visible and clean.

- Are all ground controls operating?

- Are wheels and tires undamaged and properly inflated?

- Is tip-over protection is onboard and working.

- Make sure beacons and alarm safety devices are working.

- Check the operation of the platform-control console.

- Check the hydraulic pump oil level and operation.

- Make sure the fall protection is in place and working as designed

Thomas A. Westerkamp is a maintenance and engineering management consultant and president of the work management division of Westerkamp Group LLC.

Related Topics: