Obtaining Primary Data to Help Support Energy Projects

Part 2 of a 3-part article on how facility managers should use numbers to plan energy measures and to prove they worked

Primary data, typically from data loggers, provides another basic source of useful data for an energy project. Primary data is data that you collect, versus secondary data, which is already in existence. Data in general is important in guiding energy audits (also called energy assessments) that lead to the creation of energy conservation measures (ECMs) that in turn will serve the building’s interests.

Primary data collection involves the active measurement of a building’s energy use and usually requires the installation of data loggers. Data loggers can measure and record the following in a time/date stamp for each reading: electrical consumption, electrical demand, motor run time, light levels and lighting on/off patterns, space temperatures, HVAC system temperatures (i.e., supply air temperature), relative humidity, space occupancy, and a combination of factors.

Data are available in the raw format, formatted with time/dates, exported to MS Excel for analysis, and in graphs for reports. Most facility managers like to see the graphic representation of data to more easily understand what is happening, where, and when.

Data loggers provide real-world data on what is actually happening each day in a building, versus what people think is happening or what is supposed to be happening. Data loggers can confirm what is working well and what areas need improvements, and give feedback on EMS/BAS controls, manual control efforts, housekeeping activities, etc.

Data loggers also provide accurate system run times that are part of energy-use and energy-savings calculations. Industry averages and standard operating procedures mean nothing in a professional energy audit. Each building is unique and the recommended ECMs and projected payback periods are customized to each building system. It would be hazardous for a facility manager to rely on estimates of runtime, estimates of energy savings, and estimates of ROI for an investment in energy conservation measures or mechanical ASHRAE level II energy audit forecasts /electrical/plumbing improvements.

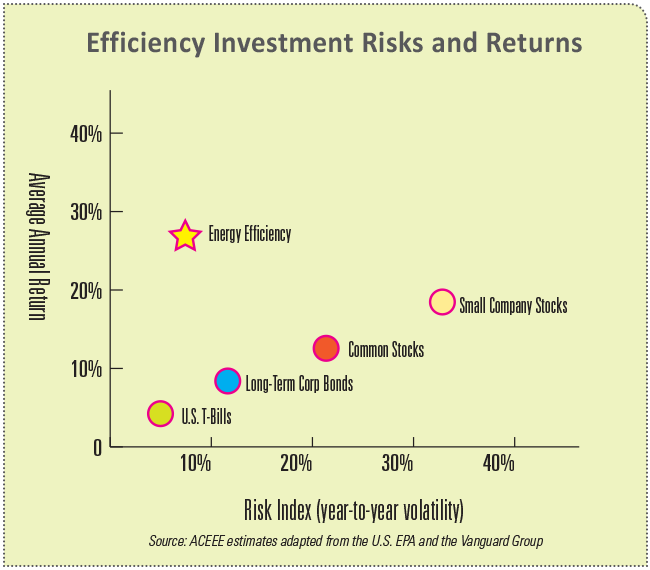

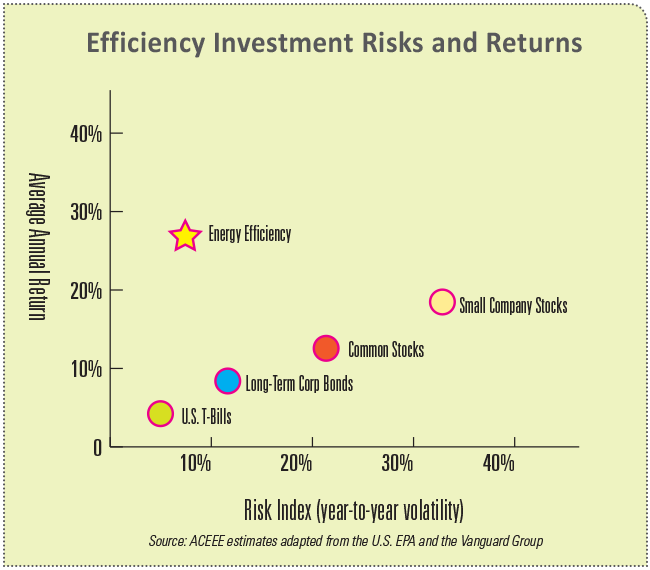

ASHRAE level II energy audit forecasts of energy savings should be coupled with a comprehensive evaluation of each building’s investment opportunity in the executive summary of the energy audit report. The shorthand version is to address each ECM and grouping of ECMs with these metrics:

Simple payback period = energy savings/capital investment

ROI = 1/simple payback period

Long-term net present value (NPV) of the energy management investment versus alternative use of the funds

The positive impact on the net operating income (NOI) leading to increased asset value or asset appreciation

Related Topics: