How to Get Retro-commissioning Right

Understand the process, the team, and the benefits to make sure your retro-commissioning process results in energy savings and efficient operations.

Retro-commissioning is typically applied to existing buildings to identify how to improve the efficiency and operation of energy consuming systems and equipment such as the HVAC system, interior and exterior lighting, and service water heating and usage. Retro-commissioning is typically a four-step process that begins with an analysis of an existing building through study of energy and water efficiency and operation and benchmarking with peer buildings. It prioritizes the list of potential capital improvements from lowest to highest. Retro-commissioning may address latent design or construction deficiencies. It develops a process to implement energy efficiency and operational improvements. At the conclusion of retro-commissioning, documentation of the process including findings and improvements is provided and is carried into operator training.

Retro-commissioning goes beyond day-to-day building maintenance by addressing high energy costs and resolving operational problems by conducting a thorough assessment of existing mechanical HVAC systems, lighting, service water systems, and automatic controls. Changes in operational demands or occupancy may require reconfiguration of the mechanical HVAC and lighting systems and associated controls. Retro-commissioning helps the owner identify and meet targeted energy efficiencies and performance requirements through extensive review of the property and benchmarking of peer properties. It reduces potential for unexpected repairs and premature equipment replacements. It also verifies that maintenance personnel are adequately trained and have documentation to operate the property for optimum performance, and helps to identify future capital outlays. Retro-commissioning takes a holistic view by observing, monitoring, and trending energy and water usage in building systems. It identifies and addresses potential HVAC operational concerns such as indoor air quality and building pressurization.

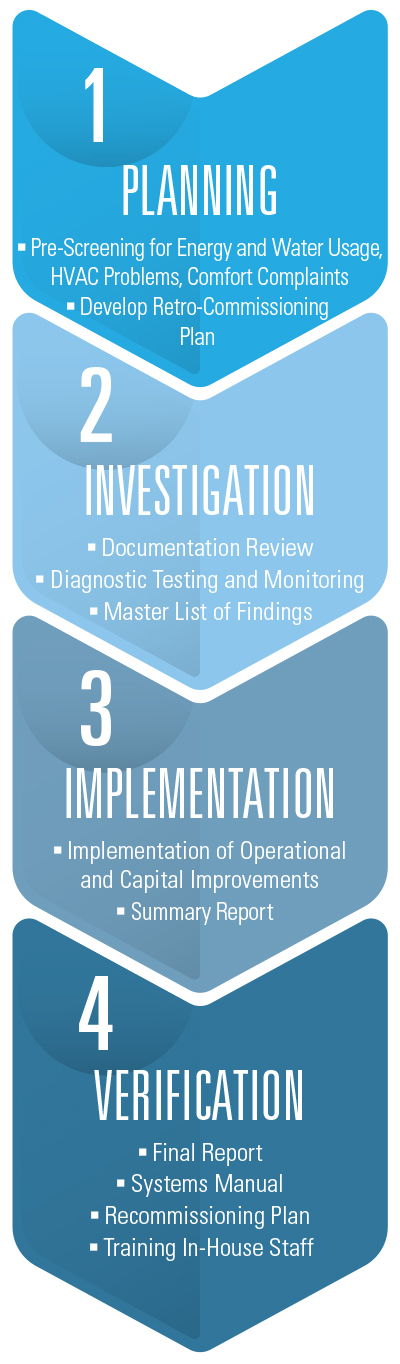

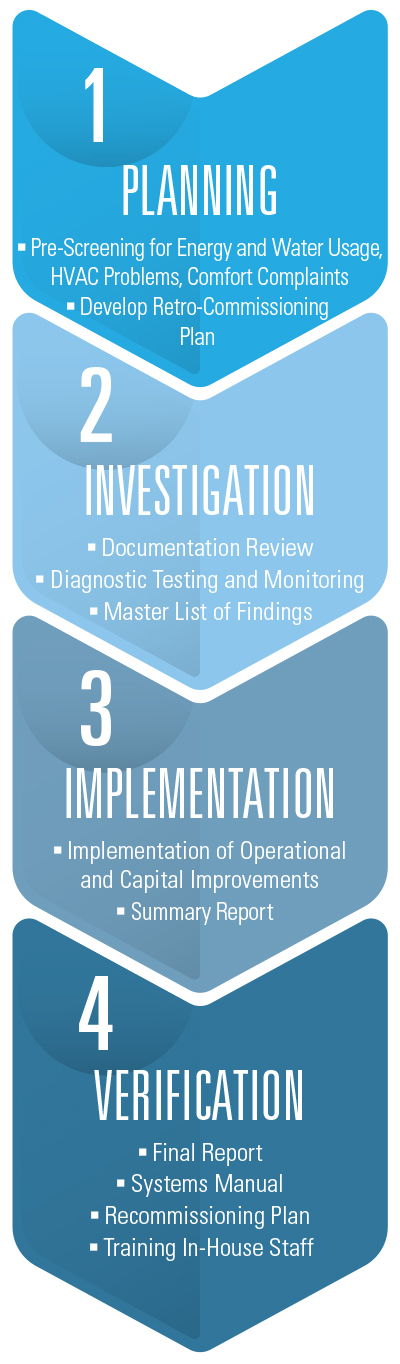

4 steps of retro-commissioning

1. Planning Phase

To determine if a building is a good candidate for retro-commissioning, a team of specialists will start by identifying equipment or systems with high energy use, with persistent failures and in need of repairs, and those which receive frequent occupant complaints regarding temperature, relative humidity, and indoor air quality. Building size and equipment age are confirmed, and building documentation is located. Next, the owner’s operating requirements are considered and factored into a plan for potential improvements. An initial site walk-through and identification of the type of HVAC and lighting controls are performed, while the capabilities of in-house staff are assessed.

2. Investigation Phase

The project team will review facility documentation such as drawings and control sequences of operation. This phase also includes performing functional diagnostic tests and low-cost repairs as part of the investigation and testing. The team will perform diagnostic monitoring of operating characteristics such as utility meters, temperature and relative humidity levels, operating hours, building indoor air pressures, and carbon dioxide levels. A master list of findings will be developed for use as a tool for decision-making. Using cost-to-benefit analysis recommendations can be prioritized with energy saving options selected and operational improvements identified.

3. Implementation Phase

The next phase is focused on the development of an implementation plan and scope of work from the master list of findings. At this point, the team will select operational or capital improvements using outside contractors and owner-led or in-house staff. The team will test improvements implemented for anticipated results. A summary report with further actions is developed.

4. Verification Phase

The final step of the retro-commissioning process is the verification phase. The team installs recorders and monitoring equipment such as utility meters, temperature and relative humidity recording tests, operating conditions, and other diagnostics. A final report of the retro-commissioning activities and measures implemented is created, including: a master list of findings, updated estimates of energy cost savings, results of performance improvements, test results, recommended frequency of re-commissioning, complete documentation, and a list of further capital improvements warranting investigation. The team will compile a systems manual including re-commissioning documentation, and operation and maintenance recommendations. They will also develop a re-commissioning plan with intervals to keep systems at peak performance. Training will be provided for in-house staff, and a hand-over meeting held to close-out the effort.

Meet the retro-commissioning team

- Commissioning lead is a third party or a member of the owner’s staff with responsibility for heading up the process of kick-off, planning, scheduling, coordinating activities, and developing a master list of findings.

- Building owner’s representative communicates the expectations of building operation and project objectives, while supporting the retro-commissioning team.

- Building manager and building staff works to enhance the overall operations and maintenance plan, and observes diagnostic trending and testing to improve staff’s understanding of systems.

- Contractors and manufacturer’s representatives such as installers, maintenance/service contractors and equipment suppliers may be needed for testing or implementation of measures.

- TAB contractor may be needed to re-balance water and air flows.

- A/E design professionals are utilized, if improvements need design, construction drawings, and permitting.

- System specialists may be needed for a particular technology such as clean rooms, fume hoods, and air scrubbers.

Benefits of retro-commissioning

Retro-commissioning usually results in improved system and equipment operation that goes beyond routine operation and maintenance. It looks at control strategies, sequences of operation, interaction of mechanical HVAC, lighting, building enclosure, and how related systems affect each other. It provides a comprehensive analysis of a building’s energy performance. Recommendations are provided on reducing energy consumption and demand charges. Improved equipment performance leads to longer life spans, more reliability, fewer repairs, and lower energy costs to operate. Indoor environmental conditions include improved room temperature, relative humidity and building pressure control.

Indoor air quality is improved by reducing moisture infiltration through the building enclosure, ensuring outside air intake is adequate, air balance is proper in providing air circulation, and air leakage and ductwork degradation is diagnosed.

Retro-commissioning improves documentation such as up-to-date operation and maintenance manuals, sequences of operations, and system diagrams. It helps devise a preventative maintenance plan and a re-commissioning plan. Retro-commissioning reduces operating expenses.

Case study: Retro-commissioning at a major hospital

Work performed by trained commissioning agents at a major hospital serves as a good example of how retro-commissioning can result in long-term benefits to the owner and occupants. The retro-commissioning team was initially engaged to address the issue of elevated room temperatures and relative humidity levels in operating and patient rooms varying from the requirements of the owner and state health statutes. Lack of building indoor pressurization by the HVAC system had led to environmental control problems.

Investigation showed the air handling systems were not reliably supplying conditioned air temperature and relative humidity to many areas. Systems were also not delivering stable indoor pressure in all areas. The solution involved retrofit of the HVAC system with direct digital controls and repair and re-calibration of the air handling systems. The building was rebalanced to the design amounts of conditioned air and outside air ventilation in all areas.

Next, new sequences of operation were developed for more accurate temperature and relative humidity control savings, and to maintain net positive indoor air pressures on all floors. Testing was completed after retrofit to verify requirements of the redesign. The retro-commissioning project resulted in improved HVAC performance, reduced occupant complaints and substantial energy savings.

Commissioning and re-commissioning

Many municipalities have adopted the 2015 and 2018 International Energy Conservation Code (IECC) for new building construction and major renovations. The IECC mandates that an independent third-party consultant employed by the building owner provide commissioning services during design and construction or major renovations of commercial buildings. Commissioning of energy consuming systems is defined by ASHRAE Guideline 0-2019, The Commissioning Process. Commissioning is an intensive quality assurance process that begins at design and continues through construction, occupancy, and operations. Commissioning has an ultimate goal of operating a building as designed and per the owner’s requirements and that staff are trained to operate it efficiently and provide uniform comfort for all occupants. To satisfy the IECC, commissioning is typically required for facilities such as commercial office and retail buildings, K-12 primary and secondary schools, governmental, and medical professional buildings and hospitals.

Re-commissioning is enacted when a building has previously undergone commissioning or retro-commissioning. This process is usually triggered by a change in occupancy, increasing energy use, operational problems, or other comfort complaints by occupants. Re-commissioning is usually recommended at routine intervals to preserve the operational benefits and energy efficiency realized in previous commissioning or retro-commissioning of a commercial building.

Jeffrey A. Miller, P.E., is a senior engineer and principal in Terracon’s Houston office. Jeff has more than 40 years of experience specializing in diagnostics, design, engineering, commissioning, and retro-commissioning of mechanical, electrical, and plumbing (MEP) systems.

Related Topics: