Planning for Trouble

Emergency response training helps managers and departments respond to and recover from disaster

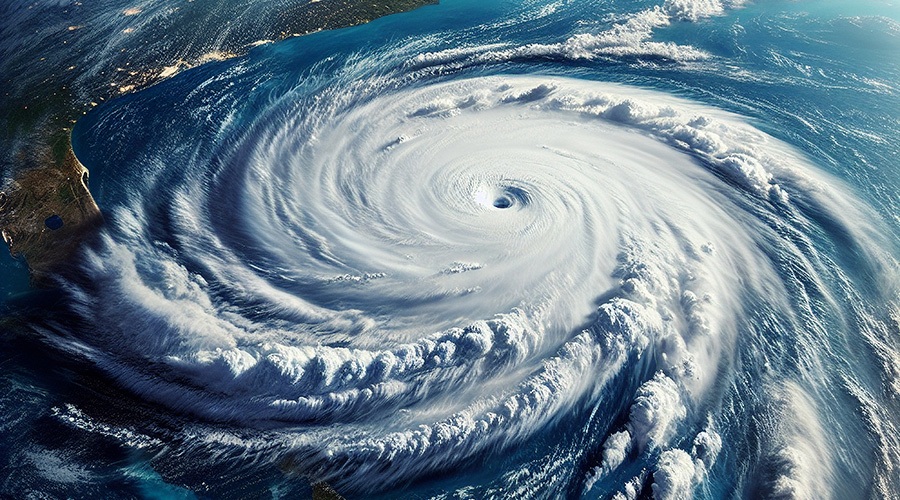

Headlines over the past few years have put emergency preparedness and response at the top of priority lists in institutional and commercial facilities. Recent emergencies include the shooting rampage at Virginia Tech, the 2005 hurricanes and flooding in the South, and the terrorist attacks of 9/11. Obviously, emergencies and disasters are unpredictable. So adequate anticipation, proper preparation and effective response can be daunting challenges for maintenance and engineering managers.

By identifying the threats, understanding the necessary resources, and developing a comprehensive staff-training program, managers can successfully prepare their departments for the ever-expanding challenges presented by emergency preparedness and response.

Planning Procedures

Managers play an integral role in helping their facilities respond to disasters and emergencies. Though each emergency is unique, any organization will be better prepared if managers plan carefully, put emergency procedures in place, train staff, and practice for emergencies of all kinds.

The first step in preparing facilities is to develop a business continuity and emergency preparedness plan that takes into account a range of internal and external emergencies that facilities might encounter. These events include explosions and fires, extreme heat, floods, hurricanes, pandemics, chemical threats, workplace violence and utility disruptions and failures.

The U.S. Department of Homeland Security has prepared a checklist to assist in developing plans or reviewing and revising existing plans. The checklist is available at www.ready.gov/business/_downloads/sampleplan.pdf. This list helps define the crisis-management team, primary and secondary command center locations, key personnel, communication systems, and required supplies. Additional items specific to maintenance include in-place shelter and evaluation plans, cybersecurity and records backup, critical operations, and equipment shutdown.

Staff Training

An emergency plan will be effective only if the maintenance and engineering staff is prepared. One key to preparing in-house supervisors and technicians is providing the necessary training. Training and education ensure that all department employees are aware of potential hazards and the steps to protect themselves and their co-workers through established policies and procedures.

Training should begin with an overview of the emergency plan and the staffs’ role in each type of situation. Specific training should include communications, warning signals and alarms, equipment shutdown procedures, evacuation plans, and shelter-in-place procedures.

The Occupational Safety and Health Administration (OSHA) has developed mandatory worker-training requirements for various emergency-response functions. Managers should evaluate the need for the following OSHA training:

• emergency action plans

• respiratory protection, including the use of dust masks

• additional personal protective equipment, such as hearing protection, protective clothing, eye protection, and hand and foot protection

• first aid and CPR

• bloodborne pathogens, including potential contact with blood or other bodily fluids

• hazardous materials and waste response

• fire safety and emergency evacuation.

OSHA training in other areas might be required, depending upon the hazards created during emergencies. Managers also should anticipate training needs related to: lockout/tagout of energy; confined-space entry; fall protection; exposure to asbestos, lead, and other toxic materials; and heat-related illnesses.

The shootings at Virginia Tech emphasize the need for a program that addresses workplace violence. OSHA provides specific guidance for facilities to evaluate and prepare their staff for violent acts.

OSHA’s web site offers managers several documents on workplace violence, including a program specific to health care and social services facilities. The guide provides a step-by-step program for addressing violence from physical assaults or threatening or violent behavior in the workplace.

OSHA also has developed a 16-hour course to prepare workers performing disaster-site clean-up operations. This course aims to protect workers responding to major building collapses after the terrorist attacks on the World Trade Center and the Pentagon.

In response to the large-scale disaster sites caused by the 2005 hurricanes in the South, OSHA has developed additional training dealing with new hazards created by flooding and extreme weather.

Practice Makes Perfect

To be truly effective, training programs should involve role-playing and simulations. Many facilities routinely perform fire and severe-weather drills several times a year. But many other aspects of emergency and disaster preparedness and response plans merely get filed away and forgotten.

So when the time comes to put the plan into effect, it fails miserably. Proper testing and continued revisions and improvements to the plan will pay major dividends should a real emergency arise.

Additional drills and emergency simulations should test the effectiveness of the written plan and training. Drills offer both managers and front-line technicians opportunities to learn and improve the department’s overall preparation and response. Managers can conduct the drills using strictly in-house personnel or in cooperation with outside agencies.

The Road to Recovery

Maintenance and engineering departments also play a central role in facility recovery operations after the emergency.

Many emergency response plans overlook the process of getting facilities back into operation. The crisis might have affected communications and utilities. Information systems might be down, and structural or architectural damage might make some areas inaccessible.

It is just as important for managers to evaluate their departments’ role on the back end of disaster response, along with its role during the initial phases of emergency responses. Managers must anticipate the types of hazards and conditions workers might encounter, then prepare them for their roles after the dust has settled.

A well-tested, comprehensive plan that identifies hazards in disaster preparedness, response and recovery will put managers in a better position to protect people, facilities and the environment during emergencies, and sound training and simulations ensure a properly prepared staff.

Jeffery C. Camplin, CSP, CPEA, is president of Camplin Environmental Services Inc. in Rosemont, Ill. He is an OSHA-approved instructor of its 16-hour disaster site worker-training course.

Guarding Physical Assets

Any organization’s preparations to prevent and respond to emergencies must include safeguarding physical assets from threats and attacks. This process begins with a room-by-room walk-through to identify vulnerable key assets and determine steps to protect and secure them.

An essential step is to assess the HVAC system to improve and protect indoor air quality during emergencies and disasters. HVAC systems can be an entry point and a means of distributing biological, chemical and radiological threats.

An HVAC assessment should include emergency shutdown, securing outside air intakes, and improving filter efficiencies. High-efficiency particulate air filters (HEPA) can capture very small particles, including many biological agents.

While these filters are excellent at filtering dander, dust, molds, smoke, and many biological agents, they are not effective on chemical vapors and gases. Managers also must develop effective procedures for HVAC isolation and shutdown to protect building occupants and assets.

— Jeffery C. Camplin

|

Related Topics: