Ports in a Storm

How three New Orleans hospitals survived Katrina, remained open amid the flooding,

and provided shelter and safety for thousands

Hurricane Katrina had come and gone. Now, communities and facilities throughout the Gulf Coast could begin to assess the damage and recover. But for officials with three New Orleans-area hospitals, the recovery process that began after Katrina struck on Monday, Aug. 26, went far beyond fixing blown-out windows and torn-off roofs. Almost overnight, managers in these facilities went from coordinating the maintenance, engineering and operations of their facilities to overseeing what amounted to small towns.

At one point after the hurricane, about 2,500 people — employees, their families, patients, their families and others — sought shelter at Ochsner Clinic Foundation Hospital, just north of the Mississippi River, which winds through New Orleans.

Another 2,000 had taken refuge in West Jefferson Medical Center, across the river to the south in the suburb of Marrero. And 1,000 more had gone to East Jefferson General Hospital, farther north near the southern shore of Lake Pontchartrain.

In the hurricane’s aftermath, managers in other area facilities wrestled with their own challenges — waiting for flood waters to subside to get into buildings, or cleaning up damaged or mold-infested facilities. By contrast, the hospitals — the only three of 15 in the area to remain open — faced a unique set of immediate and immense challenges. They became places of refuge for many who couldn’t get out of the city or into their homes. Instead, they headed for the lights of the hospitals.

“We were the only thing lit for miles,” says Paul Burke, facilities manager with East Jefferson, a 444-bed facility. “We were an island out here.” The surrounding darkness, isolation and uncertainty put hospital officials in a difficult situation.

“The biggest challenge was knowing we had to deal with whatever might come up without any outside support,” Burke says. But all three hospitals stayed open and functioning, giving the 5,500 people gathered there some stability amid the chaos.

“We remained fully operational,” says Grant Walker, vice president of support services with Ochsner. “We never shut down.”

Trouble Brewing

Weather reports before the hurricane’s arrival had projected a path that would have taken it east of New Orleans. But Walker says his staff happened to hear a report late Friday, Aug. 23, that the storm had shifted directly toward the city.

“Luckily, we caught that report,” he says. Over that weekend, department managers were able to arrange quick deliveries of key supplies — including water, food, and additional generators — from its distributor.

“It was essential to have a relationship with (distributors) outside the area,” Walker says. Among the additional supplies the 478-bed hospital stockpiled were plywood, plastic bags for cleanup, 6,000 gallons of water and air mattresses.

Meanwhile, managers at West Jefferson believed reports that the storm would miss New Orleans.

“When we left on Friday, we were prepared,” says Ronny Gann, director of facilities management with 462-bed West Jefferson. “We were under the expectation that Katrina was going to Florida. But it didn’t.“

Surviving the Storm

Katrina’s heavy rains and the ensuing flooding would devastate the metropolitan area, but all three hospitals remained open and safe from floodwaters, and high winds did relatively little damage to the buildings. At Ochsner, for example, the hurricane’s 120-mile-per-hour winds blew out eight windows and damaged another 30 or so, and they damaged or carried away numerous pieces of rooftop HVAC equipment.

“The roofs were the first problem we had,” he says, adding that high winds lifted up rubber sheets on some roofs and sent them sailing, also ripping away brick roof parapets. “Needless to say, we won’t be putting those types of roofs back on,” he says.

At West Jefferson, damage included 65 broken or blown out windows and minor roof damage. At East Jefferson, wind and wind-borne gravel roof ballast damaged 30 double-pane windows.

Just how had the hospitals managed to weather the hurricane and remain open and functional, while the rest of the metropolitan area descended into flooding and chaos? All three managers point to their facilities’ locations: The organizations’ founders and designers had located the facilities near either the lake or the river — higher ground than the bowl of New Orleans that suffered the heaviest flooding when levees broke.

“That was the key factor in us surviving the hurricane,” Walker says.

At their height, flood waters came within about 6 feet of the front door at East Jefferson, which is about 8 feet higher than the surrounding neighborhood, Burke says.

Power Problems

Once the hurricane passed, the managers and their departments began to understand the scope of their challenges. The biggest of these was ensuring an adequate supply of diesel fuel for generators powering the facilities’ medical equipment, as well as emergency lighting, elevators, boilers and chillers.

Little did managers know how long these generators would need to run. All three hospitals stayed on emergency power from 5 a.m. Monday through midnight Thursday, when electricity returned to the area.

The New Orleans weather remained steamy that week, and keeping facilities cool became increasingly difficult. West Jefferson, for example, had four portable air conditioning units on hand, but managers could not find more units before the storm hit.

“That hurt us,” Gann says. “We were going to bring in more portable units, but we couldn’t. Florida’s got them all.” High temperatures and humidity only compounded the problems.

“We had no air conditioning, and it quickly became miserable,” he says. “The temperature got above 90 on some patient floors.” To generate air movement, staff opened windows in patient rooms and activated the hospital’s smoke-evacuation system.

Ochsner’s situation was somewhat better but equally challenging. Because the hospital’s emergency power supply supports only about 25 percent of its total buildings’ air conditioning load, Walker’s department first issued a fan for each patient room, as well as for others at the hospital.

Next, the hospital’s distributor partner located and shipped in 40 6-foot fans, which technicians used to move cooled air from the hospital’s newest building — which was on 100 percent emergency power and had full air conditioning — into an older, connected clinic that had no conditioning.

The precarious situation at all three hospitals — all but isolated in a chaotic environment with finite resources — required managers and their staffs to improvise when problems arose.

For example, a roof leak at Ochsner’s power plant shorted out a generator’s circuit breaker, cutting air conditioning in one building. To remedy the situation, the hospital’s distributor partner located the part in Alabama and arranged to fly in a technician and the part by helicopter, restoring power and air conditioning.

At East Jefferson, diesel fuel concerns mounted as the week wore on. Burke had hoped to stockpile enough diesel fuel to see the hospital through the power outage, but his on-site supply of 20,000 gallons had dwindled to 3,000 by mid-week.

To remedy the situation, Burke says, a department employee called a friend at a facility about 200 miles away and arranged for a delivery of 10,000 gallons of diesel fuel to East Jefferson, keeping the generators running.

Water Woes

As managers and their staffs wrestled with power issues, they also faced mounting pressure to ensure an adequate supply of water for both drinking and sanitation. Flooding had knocked the local water utility out of service, but both Ochsner and East Jefferson had wells on site and, therefore, a supply of clean water.

“Our plumbing system was functional during and after the storm,” Walker says of Ochsner’s systems. “Our lift stations were on emergency power, and we had gas-operated pumps as back up in case emergency power failed.”

East Jefferson’s plumbing and sanitation systems also remained functional, thanks in part to changes made 10 years ago to its on-site well. At that time, hospital officials approved an upgrade to the well, which now delivers 500 gallons per minute. The upgrade came after officials discussed hurricane preparation and problems with Florida hospital officials, he says.

At West Jefferson, the situation was more difficult. A lack of water from either the utility or a well put the buildings’ plumbing system out of operation. As a result, maintenance technicians were forced to improvise by transferring water from its cooling towers to its boilers so kitchen workers could prepare food for the employees, patients and families. The hospital also instituted emergency sanitation measures in lieu of functioning plumbing.

The Human Factor

The wild card for all three hospitals, however, was unexpectedly having to meet the needs of their newly expanded populations.

First, there were the thousands of people — aside from hospital employees — who had sought shelter, food, clothing, and, in some cases, medical attention. Nurses were attending to existing patients, and maintenance technicians had their hands more than full attending to HVAC and plumbing issues. Nonetheless, all hospital employees also had to devote part of their time to helping those who had taken refuge from the storm.

“That was a tremendous load on our resources,” Gann says, adding that many of those sheltered at West Jefferson remained there for 11 days. “We had palates and air mattresses in every nook and cranny.” Ochsner’s situation was similar.

“We had staff, families, visitors, patients and their families living at the hospital for four weeks after the storm,” Walker says. “We housed folks in offices, conference rooms and our clinic. We provided three free meals a day to everyone.” In some cases, providing shelter required improvisation.

“Linen was probably the most taxed (resource),” Walker says. “Our laundry department was not on emergency power, and the well system did not have enough pressure for our washers. We had to ship our linen to Baton Rouge to have it cleaned.”

Then, there were the hospital employees, including maintenance and engineering staffers, who put in long hours to keep critical systems functioning and providing for the needs of others.

“It was seven or eight days before some of these guys got relief,” Gann says. Many worked shifts of 14-20 hours a day.

“My guys were stressed out pretty heavily,” he says. The hospital had made plans for two teams of maintenance workers to take turns on duty, but the inability of some workers to get to the hospital or to return once they left the hospital meant those remaining on site had to compensate. Staffs at East Jefferson and Ochsner faced the same challenges.

“During the storm, every maintenance employee was there in the heat of the storm, securing blown out windows, sandbagging roofs,” Walker says. “After the storm, they worked for days straight without sleep to get all of our infrastructure fully operational. The first week after the storm, they moved to our off-site clinics and brought them on line to provide health care to the surrounding community.”

The Road Ahead

As metropolitan New Orleans recovers from the hurricane and ensuing flooding, the three hospitals that remained open through it all are reviewing their responses and taking steps to reinforce facilities and improve emergency preparedness.

Preparations at West Jefferson will include securing a reliable supply of water — either a dedicated water line from the utility or a deep well on hospital grounds, Gann says. The hospital also will resume work on the new power plant under construction on the main campus, one that will address some power problems caused by the hurricane. Besides increasing power capacity, the new plant will locate emergency power equipment on the second floor about 20 feet above sea level and behind walls designed to withstand 150 mph winds.

The hurricane provided an unwelcome but necessary reminder that preparing for and recovering from a hurricane is not a one-time activity but an ongoing process.

“As we renovate and upgrade and maintain, we have to bring facilities up to hurricane standards,” Gann says. “We have been, but maybe not as diligently as we should have.”

Associations: Partners in Recovery

In the aftermath of hurricanes Katrina and Rita, associations with ties to institutional and commercial facilities have worked together to address the needs of affected maintenance and engineering departments. Likewise, managers have turned to these associations for support.

“Keep good contacts with your professional groups because they can be your biggest allies,” says Sylvester Johnson, associate vice president of facility services for Tulane University in New Orleans, which was severely damaged by Hurricane Katrina. Johnson says associations, such as APPA: The Association of Higher Education Facilities Officers, have been essential resources.

Disseminating critical information has been a challenge. To reach as many individuals as possible, some associations are coordinating their relief efforts. For example, APPA is working with www.campusrelief.org, a resource created by the American Council on Education and the National Association of College and University Business Officers. Through such partnerships, associations have address members’ needs most effectively.

“If you have too many players and too many contact points, it doesn’t help the institutions that need the assistance,” says E. Lander Medlin, APPA’s executive vice president.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has partnered with its chapters, other associations and the Center for Disease Control (CDC) to provide guidance on cleaning buildings properly to minimize risks from Legionella bacteria.

Legionella “is a very serious concern,” says Terry Townsend, president-elect of ASHRAE, adding that stagnate, warm conditions in flooded areas offer ideal conditions for its growth. “Legionella bacteria has been known in certain conditions to travel 2 miles from the source. We can’t stress enough the importance of being protected.”

Managers can obtain the National Institute of Occupational Safety and Health’s recommendations for cleaning flood-contaminated HVAC systems at the CDC web site, www.cdc .gov/niosh/topics/flood/Cleaning-Flood-HVAC.html

Haste Makes Waste

To make facilities operational again, managers might feel pressure to make repairs quickly.

“One of our biggest problems is trying to tell these folks not to be in a hurry,” says John Milnick, field representative for the National Electrical Manufacturers Association (NEMA). “I understand they want to get back in business, but these things have to be replaced properly. We see a lot of installers get desperate and substitute materials that really shouldn’t be substituted.”

For example, workers might install an over-current device that is the wrong size because that was the only one available.

“There might have been good intent to try to change it later, but as weeks go by they forget about these things,” he says. “This just creates problems down the road.” As part of their current hurricane-recovery efforts, NEMA representatives are talking with building officials in the affected areas about the dangers of installing improper materials in applications.

Take Precautions

Associations are offering guidance to managers in facilities along the Gulf and East coasts who are reviewing their buildings’ ability to withstand natural disasters.

“I think (managers) are going to have to step back and look at their facility to see where the damage could take place and do some planning,” Townsend says.

He advises managers to move critical equipment to higher floors, where flooding is not as great a concern and technicians can more easily access it. They should also get rid of materials that cannot withstand water intrusion and specify materials that are more tolerant of moist environments, he says.

Preparing for a hurricane “is going to take money and, in many cases, it’s not going to be cheap,” Towsend says. “It is going to take careful planning and effective use of resources to get buildings as sturdy and as waterproof as possible.”

— Renee L. Shroades, Associate Editor

|

Universities’ Hurricane Prep 101: Plan, Plan, Plan

When disaster strikes, it is not enough to simply hope for the best. Rather, maintenance and engineering managers know they must prepare for the worst. When hurricanes Katrina and Rita threatened the Gulf Coast in September, universities in the storms’ paths prepared in earnest. Preparations included implementing written plans to address the potential consequences if the hurricanes struck the campuses.

Sylvester Johnson, associate vice president of facility services for Tulane University in New Orleans, now is helping to restore the university’s 115-acre campus, which was severely damaged by hurricanes and ensuing floods. The university plans to reopen its 80-plus buildings in mid-January. His advice for organizations facing similar catastrophes is straightforward.

“Always have a plan,” he says. “Things don’t always go according to plan, but if you have one, at least you can make adjustments. You don’t have to start from scratch.”

C. Blake Hebert, P.E., executive director of facilities and utilities operations at Louisiana State University (LSU) in Baton Rouge, concurs.

“Managers can never do enough planning because each storm is different and generates its own set of problems,” Hebert says. For both hurricanes, Hebert and his staff took steps to protect LSU’s 400 or so buildings.

LSU’s hurricane-response plan features three levels of readiness, depending on predictions of storm severity. While some measures might not always be necessary, it is good practice to anticipate all situations. For example, because storms often damage power and telephone lines, Hebert recommends managers create a strategy to ensure communication among workers that includes two-way radios and cell phones.

Managers also should take measures before a storm hits to prepare for remediation, Johnson says, such as preparing a list of contractors. As soon as possible, they should assess the damage, list remediation priorities, and modify their plan as necessary. For example, while other campus buildings needed extensive repairs, his department’s first effort was to make a dormitory operational so it could house contractors and some essential in-house workers who didn’t have a place to stay.

While it might be impossible for managers to plan for every scenario, it is imperative to create a basic strategy and build from that, Hebert says. It can truly make a difference in minimizing damage and speeding up recovery.

— Renee L. Shroades, Associate Editor

|

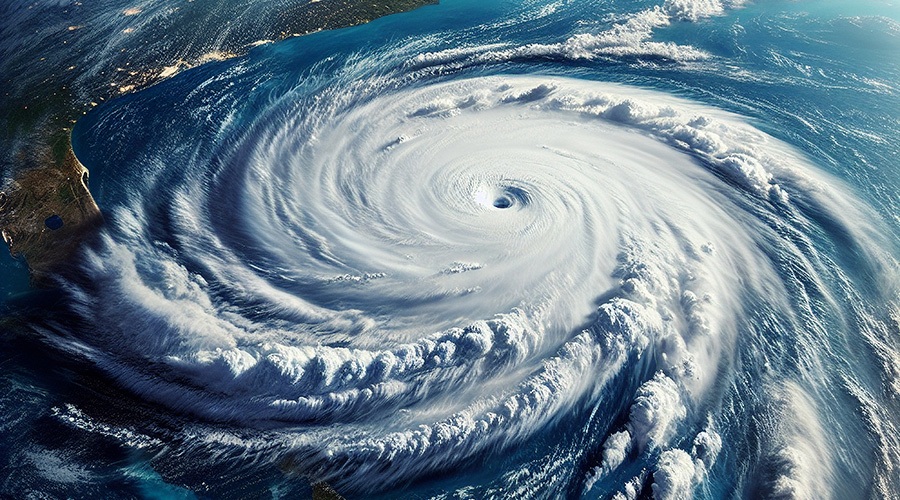

The location of three New Orleans-area hospitals, shown in red, was essential in enabling them to remain open and operational during and after Hurricane Katrina and the ensuing floods. Because the hospitals were near either Lake Pontchartrain or the Mississippi River, they were on higher ground than other parts of the area, which were inundated by floodwaters.

|

Related Topics: