Developing an Effective Arc Flash Safety Program

Arc flash safety requirements have evolved over time.

As OSHA and NFPA 70E continue to develop and enforce electrical safety requirements, it is important for facility managers to be informed about arc flash and to implement appropriate safety procedures into an electrical safety program that minimizes the likelihood of injury to employees.

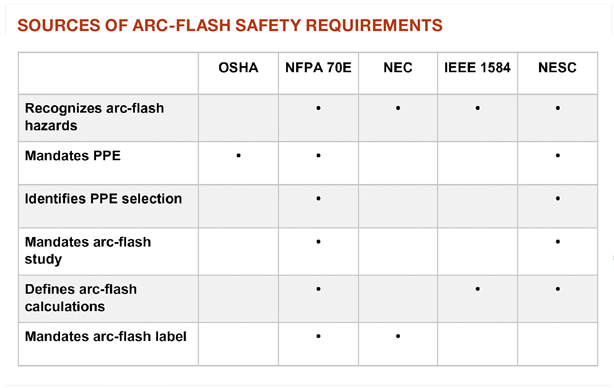

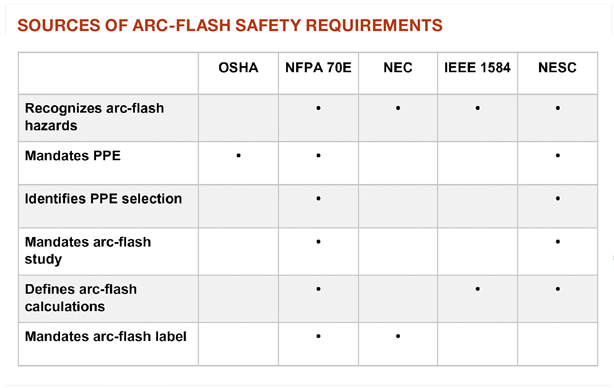

A range of regulations, codes, and standards address arc-flash safety. (See “Sources of arc-flash safety requirements” below.) The requirements of those regulations, codes, and standards are separate but cumulative; that is, they are interrelated and build on one another. All of them must be considered to develop an effective arc-flash safety program that complies with OSHA requirements.

How requirements developed

In 1970, the Occupational Safety and Health Act was passed by the United States Congress to reduce the number of job-related injuries and deaths. In 1976, NFPA 70E was developed to provide electrical safety requirements and standards for employees in the workplace. It wasn’t until 1995 that arc flash hazards were first mentioned in NFPA 70E. Since then, constant progress has been made toward determining the hazards associated with arc flash in a facility, most notably with the IEEE 1584 Guide for Performing Arc-Flash Calculations, published in 2002.

By 2011, OSHA had begun to further depart from its position on acceptable exceptions to performing work near energized equipment. Previously, employers used an exception to OSHA’s lockout/tagout requirements permitting electrical maintenance near energized parts in 24/7 facilities (i.e., equipment serving a data center’s critical business operations) due to an “infeasibility” exception stated in section 29 CFR 1910.333.

Official OSHA interpretations of that section show that this “infeasibility” exception should only be applied to situations in which de-energizing the equipment would introduce additional or increased hazards and should not be applied if de-energizing equipment would merely interrupt facility operations. Financial considerations should not be considered an adequate reason to allow work on energized equipment. OSHA continues to stress the importance of minimizing electrical hazards present in the workplace and will often cite employers who are not in compliance.

Related Topics: