UPS's Key Role In Data Centers Demands Close Attention To Preventing Problems

A typical computer can withstand only a 17-millisecond power interruption (0.017 seconds) without crashing. This infinitesimally small amount of time demonstrates why the uninterruptable power supply (UPS) system, or the electrical equipment that bridges the gap between the utility's power source and a data center's backup generator, could be the single most important system in a data center. Because of the UPS's key role in the data center, close attention must be paid to preventing problems.

It's imperative that the design of a UPS system be approached holistically, with an understanding that design, installation, and operation are intimately interconnected. Failure to address any one of these items can dramatically impact the overall reliability of the system. Here's a look at how each of these three stages should be approached and the common UPS pitfalls to avoid in each.

DESIGN

The first step is to get a good design. These seven principles can help make that happen.

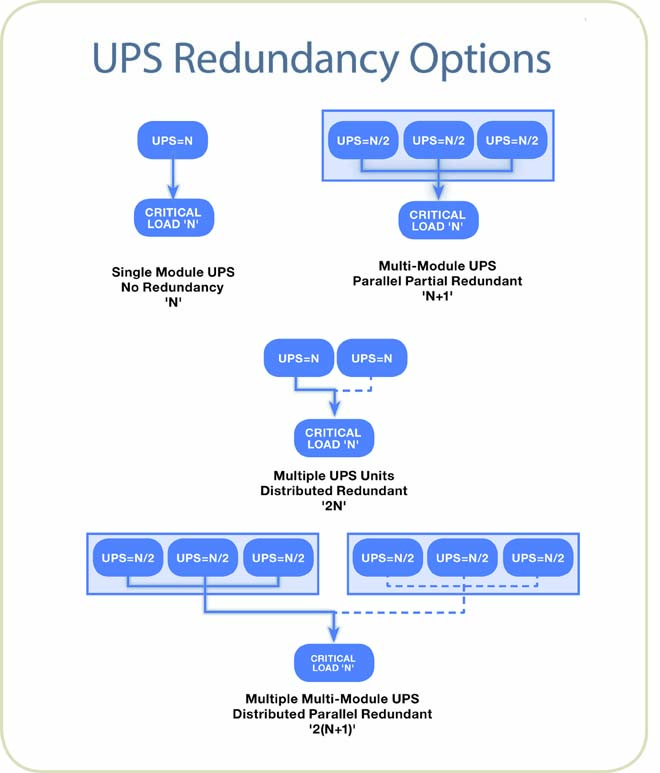

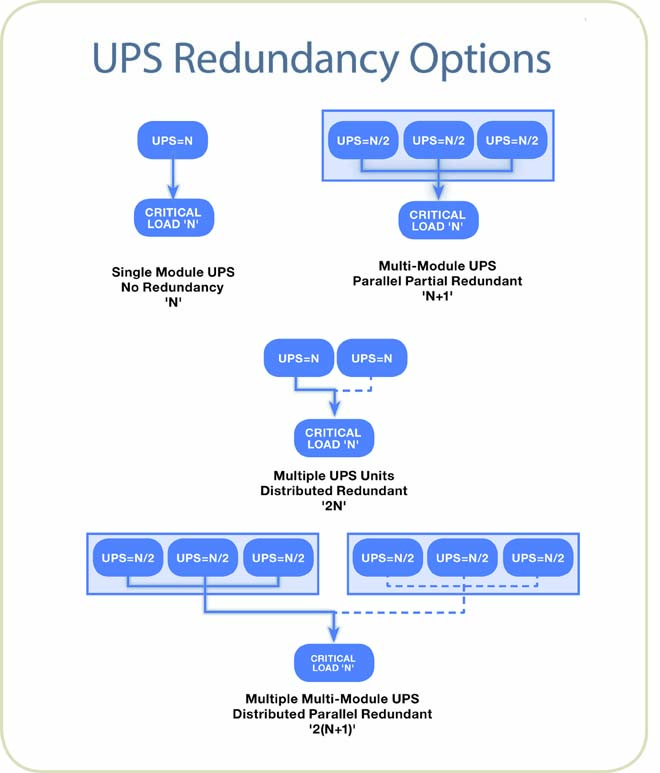

1. Choose the appropriate level of redundancy. While there are a variety of different UPS systems and configurations to choose from, selection ultimately boils down to the desired level of redundancy and fault tolerance of a data center. (See "UPS Redundancy Options" below.) If "N" is the capacity needed by the critical load, which configuration is appropriate for the mission critical environment in question?

- 1N (no redundancy)

- N+1 (parallel partial redundancy)

- 2N redundancy (distributed redundancy)

- 2(N+1) (parallel distributed redundancy)

Although each subsequent level of redundancy represents additional reliability and fault tolerance, it also increases cost and complexity. As a result, a UPS solution for a data center that processes millions of dollars of transactions for a bank per hour can be considerably different from one that supports generic commercial office operations during normal business hours.

In the vast majority of UPS installations, a simple 1N solution is perfectly adequate for the task at hand. That being said, failures can and do happen. In preparation for a potential failure, the question becomes: What amount of downtime in a year can be tolerated or what type of availability is required? Availability, or the percentage of time that the UPS system is functional, introduces the variable of mean time to repair (MTTR), as elements like unscheduled maintenance can also affect uptime. Therefore, the value of business continuity also needs to be taken into consideration when determining the required level of availability. The following equation can be helpful:

AVAILABITY = MTBF/(MTBF + MTTR)

So, with an MTBF (mean time between failure) of 100,000 hours and an MTTR of 4 hours, we can get 99.996 percent availability out of a UPS. This equates to 21 minutes of downtime a year. But 21 minutes is a purely statistical calculation. If there is a failure, the MTTR still means 4 hours of downtime before repair. And that MTTR doesn't account for the availability of parts or the response time of the service technician.

2. Keep it simple. Once the required level of redundancy has been determined, it's imperative that UPS design is kept as simple as possible to minimize complicated operations while still meeting the required level of redundancy. Beyond this, there are other external design considerations that can affect the MTBF.

Modular UPS Components

Increased modularity is a trend in UPS design that goes a long way toward decreasing the amount of mean time to repair (MTTR). Instead of an operator spending hours ripping apart a UPS to replace a single component, it's possible to replace a group of components at one time with a modular system.

The challenge of modular components is that they are proprietary to each UPS and as a UPS ages, the components may become obsolete if the manufacturer eventually stops supporting them.

It's worthwhile to develop a relationship with the maintenance and support group under contract or the UPS manufacturer itself. Reach out on an annual basis to make sure that the manufacturer is still supporting a particular UPS component model. In some cases, a manufacturer may guarantee replacement part availability 10 years or so, but don't count on it.

— John Yoon |

Related Topics: