With In-house Data Center, Heat Recovery Is Efficient Solution

Let’s take a close look at why right-sized heat recovery performed better than free cooling. The key is the in-house data center found in Chase Tower.

Chase Tower is a fully electric building, as many buildings built in the 1960s were, and when running a waterside economizer the building would have to run a boiler to produce heat needed in the lobby. The opportunity that simultaneous heating and cooling presents for energy savings is tremendous.

The constant data center load provided an option for heat recovery that performed almost 100 percent better than free cooling with decoupled heat.

Electric boilers effectively have a coefficient of performance (COP) of approximately 1kwh (1kwh of power in correlates to 1kwh of heat out); however, a heat recovery chiller has a COP ranging from approximately three to five. Simple analysis below shows that heat recovery chillers can produce the necessary chilled water while efficiently producing hot water used for heating.

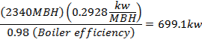

A simple calculation and equipment selection showing energy use to produce 2,340 MBH of heat is shown below:

Electric Boiler:

Using only boilers, the energy required to produce 2,340 MBH is:

Given 150 tons of cooling, a heat recovery chiller can produce 2,340MBH using 175kw. This leads to a savings of 524.1 kw and is four times more efficient.

The reason for this system being so efficient is that it provides Chase with the ability to relocate heat from their data center hydronically to their lobby, in essence using the data center servers to heat the lobby. Energy savings from heat recovery equated to approximately $175,000 per year. The final design for this heat recovery plant consisted of six modular 85-ton six-pipe heat recovery chillers. Key features of the modular design include expansion ability, redundancy, efficiency, and turn down. Another advantage of the modular chillers is their ability to match the heating load and reject additional heat to the condenser water system if necessary, simultaneous heat recovery and heat rejection.

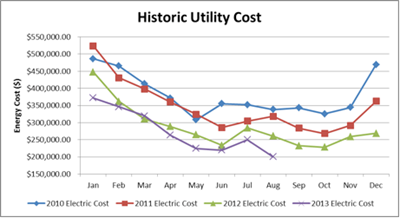

The modular chillers were installed in 2011 and have shown significant energy savings over the last two heating seasons. Figure 1 below indicates the drop in utility costs after the construction of these projects. The heat recovery efficiency can be seen in the winter of 2011 and 2012 months.

Heat recovery is a time-tested strategy that, properly applied, can dramatically improve the efficiency of a building’s hydronic system. At Chase Tower, as is typical of many office buildings, the year-round cooling requirements for technology equipment can be efficiently used to provide heat elsewhere in the building.

Daniel Cohen PE, BEMP, LEED AP is a mechanical engineer in the High-Performance Buildings Group at ESD (Environmental Systems Design, Inc.). He has experience over a wide range of market sectors including commercial base buildings, mission critical facilities, education facilities, central cooling plants, and large to small tenant interior construction projects. James Johnson PE, LEED AP, is a senior vice president at ESD (Environmental Systems Design, Inc.) with over 30 years of mechanical engineering experience. His experience includes building renovations, infrastructure upgrades, and commercial workplace projects throughout the United States.

Figure 1 Annual Utility Costs

Related Topics: