« Facilities Technology Briefs Home /

Windows & Exterior Walls

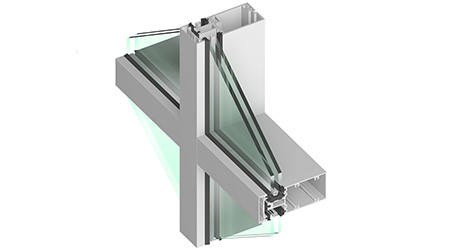

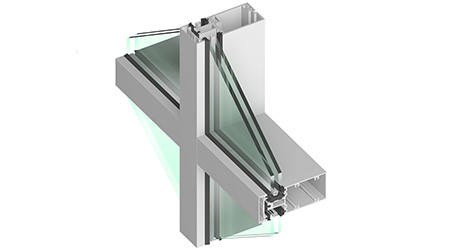

Thermally Broken Curtainwall - Tubelite - Facility Management Product Release

Tubelite

website

| Company information

400SS Series thermal, screw spline, aluminum-framed curtainwall features a thermally broken system. In addition to delivering high thermal performance (U-factors) and condensation resistance, the system is engineered for glazing in either the shop or in the field for installing on low- to mid-rise buildings.

The system can be pre-assembled, pre-sealed and pre-glazed under factory conditions, or stick-fabricated in the field. It is engineered to integrate with Tubelite's operable windows, Therml=Block entrances, MaxBlock sun shades and aLuminate light shelves.

Tubelite's 400SS Series Thermal Curtainwall's standard 2.5-inch-wide, aluminum-framed system is available in 6-, 7.5- and 10-inch depths and with an aluminum pressure plate. A polyamide pressure plate optional.

The 400SS Series Thermal Curtainwall achieves a U-factor of 0.38 for thermal transmittance using aluminum pressure plate and 0.31 using a polyamide pressure plate. It also meets the American Architectural Manufacturers Association (AAMA) 1503 standard, achieving a frame condensation resistance factor (CRFf) of 68 with the aluminum pressure plate and 77 with polyamide.

In addition, Tubelite's 400SS Series Thermal Curtainwall has been tested to AAMA 501 standards, which includes 15 psf static and dynamic water, air infiltration and exfiltration, vertical and horizontal interstory movement, seismic, and thermal cycling from -20 F to +180 F.

The thermally broken system uses a continuous 0.25-inch ethylene propylene rubber (EPDM) isolator. Silicone compatible glazing materials ensure long-lasting seals. An improved horizontal member allows for expansion/contraction clearances to minimize splice requirements.

Glass is positioned to the 400SS Thermal Curtainwall system's exterior for enhanced resistance to rainwater. The 0.5-inch bite grips insulated glass or panels of 1-inch thickness. Infill thicknesses from 1/8 inch to 1-5/16 inches also can be accommodated.

Upon request, Tubelite can provide deep face covers, captured and structural silicone glazed (SSG) verticals and horizontals, steel reinforcing, and 90-degree inside and outside corners. Modified standard and custom sizes also can be specified. An optional top-of-slab anchoring system for greater adjustability, and removable interior covers at the head and sill members, for easier access to anchors, available.

The aluminum used to produce all of Tubelite's framing systems, sun shades and light shelves can be extruded using EcoLuminum, a high recycled-content aluminum billet composition. The aluminum is finished in a choice of seven anodized finishes or 20 standard paint colors, or, upon request, blended and custom colors may be specified.

RELATED CONTENT

Content Category: Windows & Exterior Walls

FEATURES:

QUICK READS:

posted: 11/26/2018