Future-proofing a BACnet System

Integrating the BACnet protocol into a facility's BAS isn't a task to be undertaken lightly. And it's also one that needs to be implemented with the future in mind — both that of the facility and of the organization itself.

First, it's important to carefully select partners that have a proven record of understanding how to plan and execute BACnet-based building automation products and to specify control products and system vendors that have proven capabilities in the applications required. BACnet experts advise planning ahead for long-term flexibility and migration, as different control systems have different philosophies with regards to system migration and options. A system with a migration plan in place can easily adapt to new technologies with cost-effective solutions and options.

According to Kolasa, other steps facility managers can take to ensure the delivered system can be maintained with an extended life cycle include the following:

• Having a defined process to periodically back-up the system database and control equipment software and firmware to capture initial conditions and provide a recovery plan in the event of system and equipment failures.

• Ensuring that all warranty agreements and service contracts include software updates and patch management to keep systems current with the ever-changing operating system and software security environment.

• Designing an open system solution with BACnet for integration and specifying that all necessary software tools, programs and training are available to facility management personnel when needed.

The latter is key. "If the people who maintain the building don't know how the systems are supposed to work, don't have the training to use the tools the system provides and don't have the time to do anything more than react to the latest complaint call, the building is not going to operate at peak performance," Tom says. "If you include these people in your design considerations and train them on using the system, you'll provide them with the foundation they need to effectively operate the facility and minimize the natural tendency of a building to drift into inefficiency."

By following that advice, facility managers will take better advantage of the capabilities of their control systems. "All systems that do controls have some monitoring build in," says Andy McMillan, president of Philips Teletrol and president of BACnet International. Even if a system doesn't have a sufficient number of monitoring points to indicate directly that mechanical equipment isn't operating properly, the systems can provide data that facility managers can use to identify problems.

To avoid inefficiency, it's also smart to sit down at least once a year with a control engineer to compare the programmed sequence of operation to actual building use. Fellows suggests that facility managers ask engineers if the system is programmed correctly for the way the building is used today and if it meets current expectations for energy use and comfort levels.

"Benchmark your building's energy and resource usage at first completion and keep reviewing it yearly to see if anything changes," Fellows says. "Strive to improve it and solicit the help of your building automation partner to do so."

In a world of tight budgets, it may seem tempting to cut back on system integration. That can be a mistake, says Tom. "Keep in mind the building automation and control system is typically only about 1 percent of a building's construction cost and is arguably the most important tool facility executives have for maintaining effective operation of a building after completion."

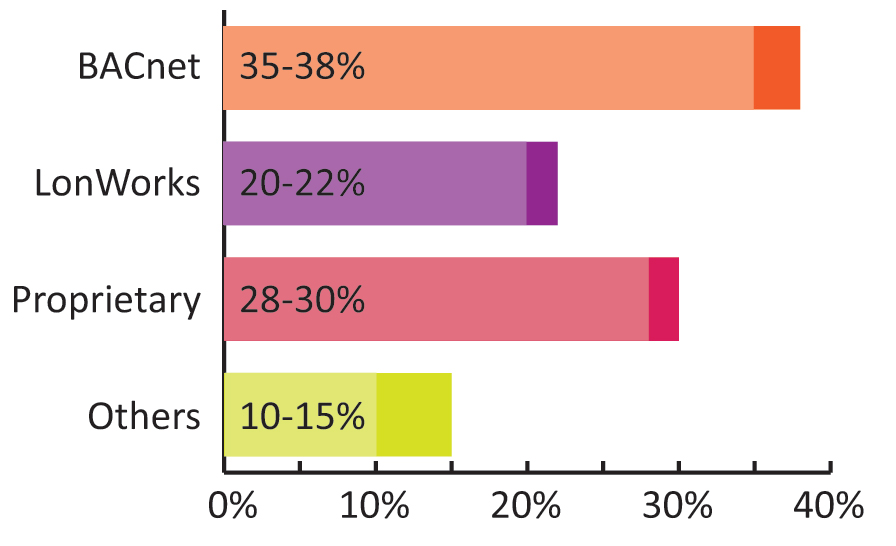

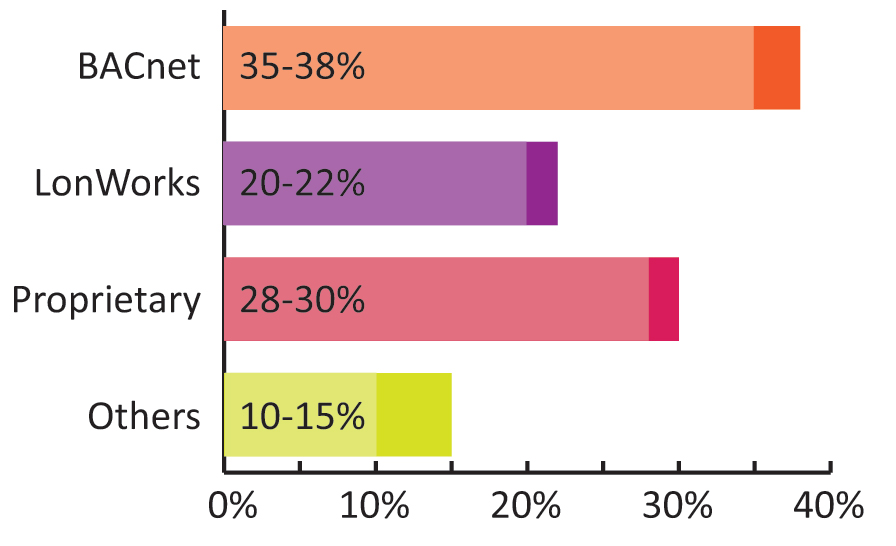

Estimated Market Share

Estimated contribution of communication technologies/protocol

in 2009 for all controllers at the top end is believed to be in the

following ranges:

Source: Frost and Sullivan |

Related Topics: