Stainless Steel Proves to Be a Smart Choice for Coastal Areas

10/25/2024

Owners and facility managers of buildings near oceans are understandably concerned about flooding. But there is another issue that should concern them – the corrosion of electrical equipment from the high salt content in coastal air. Such corrosion can lead to equipment failure, increased maintenance costs, and safety hazards.

Many buildings near coastlines faced these problems for years. The high salt content in the air accelerated rusting and deterioration of metal equipment, leading to frequent maintenance and replacement challenges. Fortunately, the use of stainless-steel finishes in electrical equipment has become more streamlined and affordable, alleviating facility managers' concerns about extensive maintenance.

Advantages of Stainless Steel in Coastal Facilities

Stainless steel is renowned for its corrosion resistance, which is a critical factor in environments with high humidity and salt content, typical of coastal regions. This finish, especially when it contains molybdenum, resists rust and corrosion better than most metals, making it ideal for use in salty, humid environments.

The tables below show the potential of stainless-steel finishes to earn high ratings from both the National Electrical Manufacturers Association (NEMA) and the International Protection Marking (IP) system. NEMA and IP are two widely recognized standards that indicate the level of protection provided by enclosures for electrical equipment.

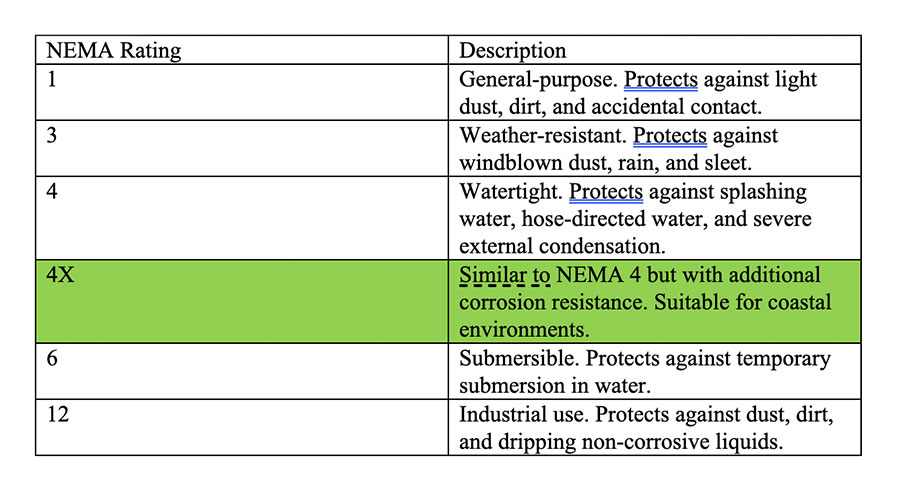

NEMA Ratings

NEMA ratings define the environmental conditions that an electrical enclosure can withstand. These ratings are crucial for ensuring that equipment can endure specific environmental factors such as dust, water, and corrosion. Below is a table summarizing common NEMA ratings. Most stainless-steel finishes achieve 4X.

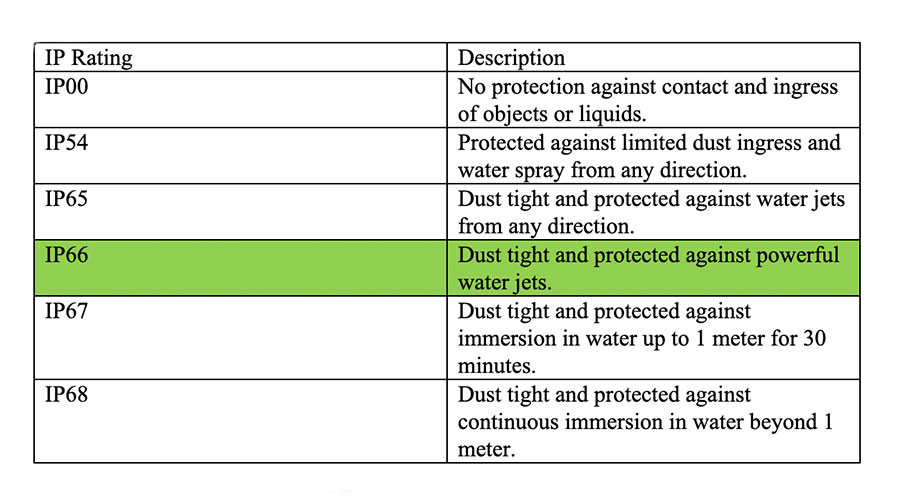

IP Ratings

The IP rating system, also known as Ingress Protection ratings, provides a more detailed description of an enclosure's protective qualities. The IP rating consists of two digits: the first indicates protection against solid objects and dust, while the second indicates protection against liquids. Here most stainless-steel finishes achieve IP66.

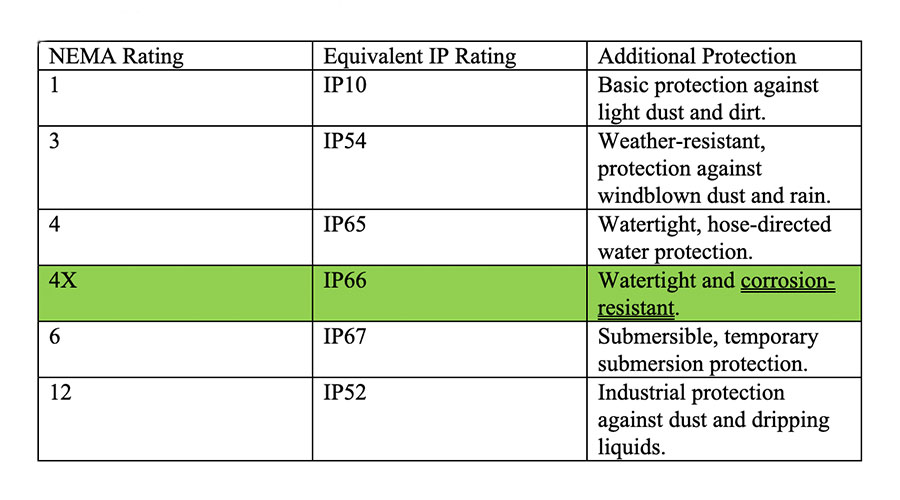

Comparison of NEMA and IP Ratings

While both NEMA and IP ratings provide valuable information, they are not directly interchangeable. NEMA ratings cover additional environmental factors like corrosion and construction details, while IP ratings focus on ingress protection from solids and liquids. Here is a comparative overview:

As the above charts suggest, stainless-steel finishes are well positioned to earn the ratings that equate to reliable protection in coastal environments.

Other Advantages

Corrosion resistance is not the only benefit of stainless steel. Other advantages include:

- Durability: Stainless steel is incredibly durable, providing a long-lasting solution that reduces the need for frequent replacements and maintenance.

- Hygiene: Stainless steel is easy to clean and maintain, which is particularly important in facilities where cleanliness is paramount, such as industrial buildings and commercial kitchens.

- Aesthetic Appeal: The sleek and modern appearance of stainless steel fits well with the architectural designs of contemporary facilities.

The use of stainless-steel electrical equipment in facilities is a strategic choice to combat the challenges posed by harsh coastal environments. There are alternatives, such as special finishes and paint on equipment, but these are not as durable as stainless-steel finishes. Stainless steel is the option that offers corrosion resistance, with high NEMA and IP ratings; durability; and hygienic properties. Therefore, it’s an ideal material for ensuring the longevity and reliability of electrical systems for critical infrastructure in coastal environments.

By choosing the right stainless-steel electrical equipment with appropriate protection ratings, coastal facilities can significantly reduce maintenance costs and improve operational efficiency, ensuring a safer and more reliable environment for all users. Although the initial cost may be a deterring factor for the owners, the cost/benefit analysis on the longevity and reduction in maintenance of the equipment should make a persuasive case for stainless steel as the material of choice.

Sam Mahdavian is associate partner at Syska Hennessy.