Tightfisted Ways to Cut HVAC Costs

No budget for new equipment? Don't give up.

A little money and a fresh look at what’s already in place can bring big savings

Energy costs for HVAC systems can be reduced through many small efforts requiring little or no capital investment. Reputable building management firms have claimed up to 24 percent savings from the latter, making such actions worth a close look.

Some of these measures might be called low-cost — that is, they pay for themselves in a year or less through avoided energy expenses. Other steps qualify as no-cost because they require only staff time.

Where can facility executives find such low-cost/no-cost savings? Four areas are worth looking into:

- Controlling outside air more effectively

- Fully exploiting existing capabilities

- Minimizing simultaneous heating and cooling

- Using more efficient replacement components

What may be cost-effective at one facility, however, may not be at another. Even if an option has no out-of-pocket expense, savings may vary because of local climate, current energy pricing, type and age of equipment, use of an energy management system, and staff availability, knowledge and experience.

Get the Most Out of Outside Air

Depending on local climate and the amount of air being recirculated in a building, conditioning outside air may account for a significant portion of cooling load. Spaces that can hold many people at one time (e.g., theater, auditorium) and those that cannot recirculate air due to tasks being performed (e.g., labs, hair salons) spend a lot to heat, cool, humidify or dehumidify outside air before bringing it into a building. In such cases, existing VAV control should be maximized. At some times, it may be possible to reduce air flow to a lower minimum level without violating fresh air requirements. Flow measurements and a check of the building code could yield major savings at practically no cost.

Even where most air is recirculated, however, judicious use of outside air can help cut HVAC bills. An economizer cycle uses outdoor air instead of return air to cool a space when the outside air is significantly cooler and dryer than return air. Depending on outdoor humidity, using more outside air in the 60-65 F range may provide some “free” cooling. When outside temperature is sufficiently low (below about 52-57 F), chillers may be shut off and 100 percent outside air used to perform all necessary cooling. Doing so may involve only changes to EMS programming or alterations to outside air damper linkage settings.

With a bit more sophisticated programming, and possibly the addition of a humidity sensor, even higher temperature outside air may be used, especially in dry climates. By comparing return air wet-bulb (instead of just dry-bulb) temperature to that of outside air, the differential enthalpy value is taken into account (enthalpy measures the total heat content of air, including that held by its moisture). Dry air in the high 60s F may hold much less total heat than moist return air, for example. From the point of view of a cooling coil, maximum use of such outside air makes its job easier.

To maintain an odor-free facility, close outside air dampers as far as possible. Outside air intakes should also be closed at the end of the working day. In spaces that are chronically occupied after 5 p.m., add a window air conditioner that can exhaust air, or a local exhaust fan, so that large air handlers may be shut down at the end of the typical workday. Look for units with built-in timers that shut units off when occupancy is highly unlikely.

As outside air dampers age, they may not close fully or seal tightly in the closed position. Adding edge seals (flexible plastic strips designed to improve sealing) may be an inexpensive way to cut damper leakage, especially in cooler northern climates.

Avoid over-conditioning outside air. In one case, seasonal settings for humidity were reversed in an EMS, forcing wet summer air to be dried to about 35 percent humidity and humidifying dry winter air to 65 percent. The building was comfortable, but chillers had to labor to remove the extra moisture, reheat coils worked overtime to keep anyone from getting a cold shoulder, and electric humidifiers raised winter power bills to a new high. Unless special health requirements are involved (for instance, in a hospital), try humidity settings that are lower in winter and higher in summer. In a one-day test, shut off winter humidification. You may be surprised to find that nobody notices it.

Outside air may be used to pre-cool at night by pulling heat from the considerable mass of a building’s floors and interior structure. Cooling such materials with night air reduces chiller load during the first few hours of the next day. Research is needed before pursuing this option, however. Where night electric rates are roughly the same as daytime rates, or evening air is humid, the net effect may be to raise, instead of lowering, energy bills. Even assuming night dry-bulb temperature is low, the cost to run fans for 8 hours may be equivalent to or greater than the avoided chiller energy from storing cooling in a building’s mass. If moist night air is taken in, a chiller may have to work harder to bring humidity down to an acceptable level, even if a space’s dry-bulb temperature was lowered by use of night air. If a chiller runs on natural gas (instead of electricity), the calculation becomes even more complicated.

Outside air may be used to pre-cool at night by pulling heat from the considerable mass of a building’s floors and interior structure. Cooling such materials with night air reduces chiller load during the first few hours of the next day. Research is needed before pursuing this option, however. Where night electric rates are roughly the same as daytime rates, or evening air is humid, the net effect may be to raise, instead of lowering, energy bills. Even assuming night dry-bulb temperature is low, the cost to run fans for 8 hours may be equivalent to or greater than the avoided chiller energy from storing cooling in a building’s mass. If moist night air is taken in, a chiller may have to work harder to bring humidity down to an acceptable level, even if a space’s dry-bulb temperature was lowered by use of night air. If a chiller runs on natural gas (instead of electricity), the calculation becomes even more complicated.

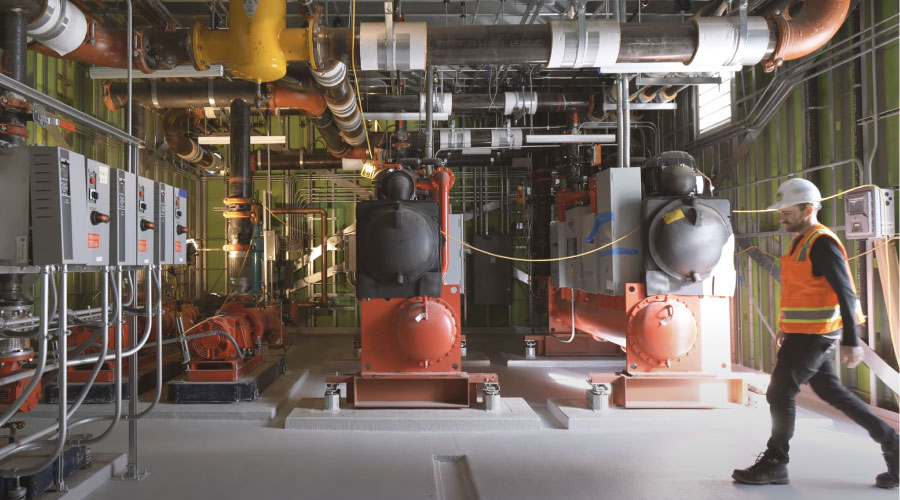

Commissioning pays

Commissioning (or re-commissioning) can lead to significant improvements in energy efficiency. Although full commissioning is not a no- or low-cost measure, it is well worth considering.

|

Night cooling generally works best where off-peak electric rates are only a fraction of daytime rates and night air is relatively cool and dry for many hours during the cooling season. The latter condition is found most often above the 40th parallel, roughly north of Washington, D.C., Salt Lake City, and the Kansas-Nebraska border.

To tightly control both the temperature and humidity of air leaving diffusers, many air conditioning systems make air sufficiently cold to condense moisture out of it, and then add heat to raise it to a comfortable discharge temperature. In such cases, HVAC energy may be reduced through more sophisticated control routines that cost little to implement.

Some ducted systems use heating coils called reheats, while others have hot and cold air ducts that mix air to the correct temperature before discharging it into rooms. Four-pipe fan coil units use built-in heating coils located next to cooling coils to perform this function. Heating and cooling occur simultaneously in those cases, and must be controlled to avoid higher-than-necessary cooling bills.

Opportunities to reduce costs may arise due to changes unrelated to HVAC systems. When internal loads are reduced (e.g., through a lighting efficiency upgrade), discharge temperatures could, for example, be raised to minimize reheating. Depending on the A/C system’s sequence of operation, such a reduced cooling load may otherwise result in an increase of reheat energy instead of a reduction in cooling energy. That’s one of the reasons that assuming a lighting upgrade reduces cooling load can be erroneous. In some cases, it may be possible to shut off reheats and simply raise the cooling coil discharge temperature. In high humidity regions, different control strategies may be needed.

Automatically resetting cooling coil discharge temperatures based on the mixed air condition (i.e., the temperature and humidity of the mix of fresh and return air) may also minimize simultaneous heating and cooling.

When set at a constant level, cooling coil discharge temperatures are designed to handle the hottest and most humid conditions, which means they are probably overcooling the rest of the time. Re-programming the facility's energy management system may be sufficient to accomplish these changes.

Small Investments

Where standard thermostats exist, consider replacing them with programmable units or units that can be operated as control points via an existing energy management system. Automatic temperature setbacks will allow significant savings during off hours at very low-cost. Some thermostats have variable deadbands that may allow wider variation of room temperatures before cooling or heating is added. Where comfort is not crucial, such as in lobbies, hallways and storage spaces, wider variations mean less HVAC use.

When combined with wide deadbands, demand control on fans will allow shutdown or slowdown on variable speed fans until a thermostat calls for heating or cooling. Such control is most appropriate when a space is not always occupied. Duty cycling, in which fans are fully shut down for portions of an hour in proportion to need, has also been used to reduce air service. However, increased wear due to much greater start/stop activity and the advent of low-cost two- or variable-speed motors have nearly eliminated this practice.

Depending on the air handler, higher efficiency filters may be installed, but be sure to verify filter compatibility with the air handler’s manufacturer. Be aware, however, that “more efficient” can have two meanings: better at capturing dirt, or a lower pressure drop across the filter, allowing better air flow. Some thought should also be given to how improved airflow will affect energy usage; more air could increase coil and fan motor load, though improved air circulation could allow a higher discharge temperature (thus cutting chiller load) if reset after the new filters are installed.

Pipe and duct insulation is inexpensive, and can greatly reduce heat loss or gain. Where insulation has been damaged, replace it with material having an even higher R-value than previous insulation. Be sure pipes and ducts that run through unheated spaces are insulated, especially if exposed to outdoor conditions, such as on rooftops. Also, don’t forget to insulate valves controlling flow of steam and chilled and hot water.

Minimize pressurization resulting from the stack effect and settings for exhaust/supply fans and dampers by sealing off service tunnels and shafts so they neither pull conditioned air from, nor leak hot air into, conditioned spaces.

Take Full Advantage of Existing Equipment

Close examination of as-built plans often reveals potential for savings by more fully using existing systems’ capabilities. In several cases, two-speed cooling tower fans have been found to exist but no control was ever implemented to allow them to run at low speed whenever possible. A small cost may be involved to add a condenser water thermostat that allows high speed operation only when that temperature is exceeded. Cutting a tower fan’s speed by two thirds (common for a two-speed motor) may reduce its electric consumption compared to full speed operation by almost 90 percent. Where towers have multiple cells, sequence fans to condenser water temperature so that some fans remain off until the peak condition occurs.

While many facilities have variable speed drives (VSD) on fan motors, it is surprising to find that many have been reset to run at full speed all the time. One common reason behind such waste is a cooling complaint occurring near the far end of a duct run on a very hot day. If the VSD is controlled based on return temperature at the air handler, it is responding to an average condition, not the hottest space. Maintaining full speed flow may indeed resolve the problem at the far end of the duct on that very hot day, but the rest of the time excess cooling and fan energy is being used. Programming based instead on the temperature of that distant room would allow full flow when needed but reduced flow at all other times.

When heating or cooling is not needed, hot and chilled water pumps may be shut off or duty-cycled, saving on electricity. Some facilities use outdoor temperature settings to control this function via their EMS.

Startup and shutdown times for chillers may also be reset automatically by EMS programming routines based on a combination of outdoor and indoor temperatures taken at specific times and temperature forecasts. Such optimized control reduces chiller plant operation to a minimum, adding up to real savings over time.

MORE CHOICES

Cooling Tower Tips Can Lead to Further HVAC Energy Savings

Through evaporation and conduction, cooling towers reject the heat accumulated in a building. When towers are able to do so efficiently, chillers (which collect building heat and send it to the cooling tower) may be more efficient. Where cooling towers are exposed to direct sunlight, heat rejection becomes more difficult. If located outdoors, planting a few trees nearby or otherwise shading it can help greatly in sunny climates.

Cooling towers use fill material such as corrugated plastic sheets that expose sprayed water to air, allowing it to cool faster and more efficiently. Keep the fill clean to enhance its evaporative effect. Tower fill must be occasionally changed, and some tower vendors offer high efficiency fill that may slightly increase a tower’s cooling capacity. The next time tower fill is to be replaced, install the better fill and assess its ability to reduce condenser water temperature on hot days.

Depending on system design, a tower may provide some “free” cooling. Called thermocycle, this process uses the natural cooling effect of evaporation instead of mechanical cooling. Used mainly where fall and winter cooling is necessary, this strategy may save a surprisingly large amount of chiller energy because some chillers are not efficient at low winter cooling loads.

— Lindsay Audin

|

Lindsay Audin is president of EnergyWiz, an energy consulting firm based in Croton, N.Y. He is a contributing editor for Building Operating Management.

Related Topics: